| Written by: The PVinsight Team

How PVinsight Spun Out from Nelson Mandela University’s PV Research Group

PVinsight is a spin-out company of Nelson Mandela University, a fact we always lead with in any company introduction because of the immense pride we all have in the university and the importance that the company puts on ethical research and academic integrity. Nelson Mandela University is also the alma mater of all our founders and the majority of our staff, further strengthening our connection and commitment to the values and excellence the university represents. But to understand where PVinsight is today we have to go back to explain the origins of PV research at Nelson Mandela University.

Early Days

Laying the Foundation: PV Research Group

Laying the Foundation: PV Research Group

The history of PVinsight begins in the Physics department of the University of Port Elizabeth (UPE) with Prof Ernest van Dyk. After completing his PhD at UPE in 1994, Prof van Dyk spent a sabbatical at the National Renewable Energy Laboratory (NREL) in Golden, Colorado, USA from July 1995 to June 1996. The work at NREL involved the indoor and outdoor characterisation of PV modules and systems. The laboratory work included standardised test procedures and studies on cell and module defects and degradation, while the outdoor characterisation included detailed monitoring and analysis of operational PV systems comprising different PV technologies. The experience there and the techniques learnt inspired Prof van Dyk to continue this research on the return to South Africa.

In 1998 Dr Freddie Vorster from the Port Elizabeth Technikon, joined the PV Research Group as a part-time MSc student to continue research into Concentrator PV (CPV) technology. This early-stage research on a new PV device technology at that time, culminated in an MSc completed by Dr Vorster in 2001.

A further sabbatical in 2002/2003 by Prof van Dyk at the Materials Science and Engineering Department at North Carolina State University led to the expansion of materials and device characterisation and the development and use of advanced techniques for the characterisation of Si and high concentrator PV cells.

The growth of the PVRG beginning in the late 90s and continuing into the 2000s coincided with the rapid development of new and exciting PV characterisation techniques such as Light Beam Induced Current (LBIC) mapping, Thermal Infrared Imaging (T-IR) Electroluminescence (EL) imaging. Development work on existing characterisation techniques such as onsite and lab-based Current Voltage (I-V) measurements, module shunt and resistance testing as well as shading susceptibility testing continued through various research and industry projects. Research activities in the CPV field continued with the development of a unique LBIC technique for the characterisation of high- efficiency CPV cells. This research was conducted as part of Dr Vorster’s PhD study that was awarded in 2007.

The blend of materials, devices, PV modules and systems research has enabled the PVRG to become a recognised research group with strong national and international links.

2006

The Physics department’s experience in semiconductor physics led to the research focus on Photovoltaics and ultimately the Centre for Energy Research (CER) was created. The CER was established in 2006 as a research-based entity with the mission of striving to serve the energy research needs of Africa through training students and conducting applied energy research.

Under the leadership of Ernest van Dyk and Freddie Vorster, the PVRG continues to be the leading research group in the PV industry in South Africa, focusing on PV module characterisation and degradation. Publishing over 200 journal articles and conference outputs in the fields of Photovoltaic (PV), Electroluminescence (EL), Laser Beam Induced Current (LBIC), Energy yield and monitoring. The expertise that was developed in the PVRG did not go unnoticed since the demand for ad-hoc testing of PV modules and systems by private companies started growing. These were often conducted through short-term contract research partnerships or once-off testing services.

The involvement of post-graduate students in PV industry research proved to be very beneficial to all parties since the PVRG gained first-hand experience on all the latest technical issues that the PV Industry was experiencing. These issues inspired formal research projects and investigations into fields such as; the effects of micro-cracking and “snail trails” on PV module performance, Light and Potential Induced Degradation (LID) (PID) as well as Light and elevated Temperature Degradation (LeTID). New, innovative characterisation techniques to study these phenomena were developed as part of Masters and Doctoral studies.

2014 – 2015

From Academia to Industry:

The first project was just a few modules, completed in the basement of the Physics department, where our original Optosolar A+A+A+ Solar simulator was installed. It was immediately obvious that more space was needed to receive modules than was available on South Campus so lab space was rented from CSIR in Gomery Avenue. An old welding workshop space was quickly converted into a lab space with a dark room for the Solar simulator and EL camera and a High voltage area for the insulation resistance tests.

In 2014, as the South African PV industry began to grow with the development of REIPPPP Bid Window 1 projects, there was a need to provide testing services to the industry. These utility-scale projects required quality assurance, mainly to ensure that the initial specifications were met and ensure the annual degradation of the deployed modules was monitored and measured. The PV Testing laboratory (PVTL) began operating within the NMMU CER to provide these services. Guided by Dr Freddie Vorster and Prof Ernest van Dyk, the setting up of the lab was tasked to then Physics PhD Student Jacqui Crozier McCleland and the then PR administrator Mariska (Müller) Swanepoel. The lab was started in collaboration with Spanish company Enertis, which is now Enertis Applus+, and functioned as their South African Laboratory to provide these tests for the new PV plants.

By December 2014, we had our first large contract and hundreds of modules were tested for Power and EL. The project was completed with an all-hands-on-deck approach and when the last module was safely packed back in its crate, the entire research group and student helpers were relieved to have completed the project.

In the beginning, the learning curve was sharp, trucks of modules arrived with no forklift or forklift driver to offload. But a forklift was quickly procured and our CEO, Prof Ernest van Dyk, added a forklift driver to his many skills and certificates.

To minimise the carrying of modules between tests, a set of trolleys were custom-designed and built to move the modules into the temperature-controlled lab and through all the test stations. Once testing was in full steam the sound of trolleys clattering across the cement floor and banging into one another as they moved through the lab was unmistakable, and when the lab fell silent you knew there was a hold up somewhere in the process.

Between 2014 and 2020, the development of new REIPPP projects stalled, and these delays meant that there were fewer large projects to test. The volume of testing work grew within the constraints of the uncertainty in PV industry at this time. A few PV plants had committed to the long-term goal of monitoring the annual degradation of their PV modules and these modules became annual visitors to our lab. These modules were welcomed back each year, to check the power output and check for new cracks or defects and ensure that the degradation in power was in line with expected limits before being carefully repacked and sent back to their plants.

2016

Setting the Standard: PVTL becomes accredited

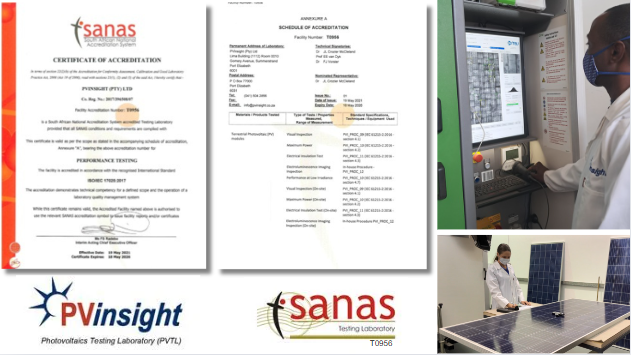

A Quality Management System [QMS] was put in place from scratch by Mariska and Jacqui. Starting with a few pages of procedures and a QMS CD-ROM ordered online and with excellent feedback from an external consultant, it was built into a robust and thorough ISO 17025 compliant QMS. In 2016, during our first SANAS assessment accreditation was awarded with no non-conformances. And the PVTL was given accreditation number, T0700.

Innovative Roots: How Nelson Mandela University Fostered PVinsight

The commercialisation of the PVTL was supported by a Technology Innovation Agency (TIA) seed fund grant which was awarded through the NMU innovation office in 2015. Throughout its lifetime, the PVTL has been championed by the Mandela Innovation Office, led originally by Jaci Barnet and Mary-Anne Chetty and now by Dr Nqobile Gumede. This dynamic team provided the direction and push towards moving the lab towards commercialization. In 2016, Mary-Anne passed away suddenly, which was a considerable loss to PVi and the NMU innovation community and anyone who knew her and the considerable value she still had to contribute to the field.

Mary-Anne had supported the PVTL from the very beginning, the first seed fund grant and was actively involved in the establishment of the lab and pushed for the commercialisation of the service. The 2016 NMU Innovation of the Year was awarded to the PV team, and this was dedicated to her and her contributions to the lab. Her strength, persistence and sense of humour are sincerely missed by the Founders, as she was both a colleague and a friend.

2017

Same campus, different name:

PVinsight continues to operate in the same lab space, as the University purchased the campus from CSIR and it is now the beautiful Ocean Science Campus. We have adapted the space to deal with the new equipment and increasing number of staff. Adding offices, more desks and retiring the trolleys (no more headaches 😊).

On 20 July 2017, the University was renamed Nelson Mandela University.

PVinsight was founded:

PVinsight (Pty) Ltd was established in 2017, in order to assist in the commercial and operational support and officially spin-out from the university with the creation lead by the Founders of the PVTL, Ernest, Freddie, Mariska and Jacqui.

The early years of the company were supported by the insight and advice received by independent consultant Wendy McCallum, who became PVinsight’s first Non-executive director. She patiently sat through many a “what are we supposed to do now?” directors meeting.

Bridging the Gap: Academic Innovation Meets Market Demand

Since 2017, PVinsight has worked with GeoSUN as our South African Sales Agent and continue to benefit from their strong local PV market presence.

2019

Research to Reality:

In 2019, NMU procured the first PV Mobile lab in South Africa from MBJ, allowing PVinsight to offer laboratory testing services at PV plants across South Africa. These tests are covered by the laboratory accreditation making it one of the few accredited mobile labs in South Africa.

The Procurement of the MBJ mobile lab 3.0 strengthened our relationship with German manufacturer, MBJ Solutions. The system has combined the EL and Power tests allowing for easier and faster testing.

2021

Good bye T0700, hello T0956.

When our 5 year SANAS accreditation cycle ended in 2021, it was decided to reapply as PVinsight. A change in legal entity means the accreditation number changes too. The SANAS assessment of the PVinsight laboratory was held online as was standard in the Post-COVID year and was relatively straight forward as the lab had started from 2020, to move the majority of lab records to soft—copies.

2022

The increasing size of PV modules meant that in 2022, a new MBJ mobile lab was procured by PVinsight and this lab is currently the only trailer-based system MBJ Solar simulator in the world. Our staff has expanded to include additional admin/support staff and technicians. Our on-site Testing efforts were spearheaded by the Dr Monphias Vumbugwa as the first full-time technician employed by PVi. His dedication and resourcefulness brought to these projects has led to the growth in the on-site testing such as EL imaging, IV curve testing.

2023

PVinsight tests 20 000th PV module!

An impressive milestone that would not have been possible without our hardworking technicians and student assistants, both past and present.

The reward for the achievement was a delicious cake, shared with the entire lab.

Here’s to many more PV modules being tested in the future.

2024

In 2024, we began working with German company, AEPVI to improve the high volume Electroluminescence (EL) testing service and this lead to dramatically increasing the speed at which new EL images can be captured. The ability to identify defects and module issues in a large sample in the PV plant and allowing that sample to be extrapolated across the entire plant to give a clear idea of the cause of module failures present.

The PVi has worked to stay engaged with the research community and participate in industry and community events.

Future Horizons: WATT’s Next for PVinsight?

As the PV industry in South Africa continues to grow, so does PVinsight’s commitment to ensuring the quality of PV modules. We look back on the early days of testing a few modules and the processions of trolleys, handwritten test sheets and temperamental equipment fondly and see how far we have come.

Our team is constantly working to innovate and improve our testing methods. Stay tuned for updates on the latest projects and breakthroughs from our lab. We’re watching closely to ensure we stay at the forefront of PV module testing technology!